Back To Blog

Back To Blog

EMI Diagnostics: Motors

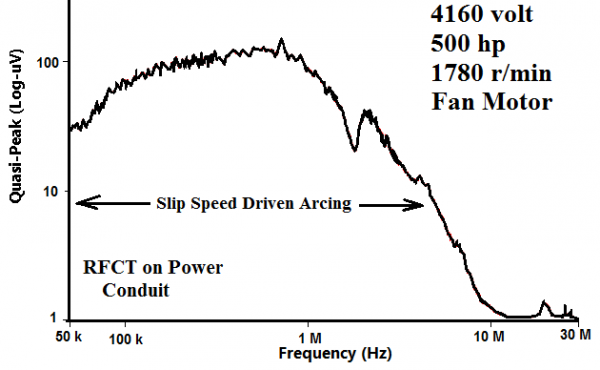

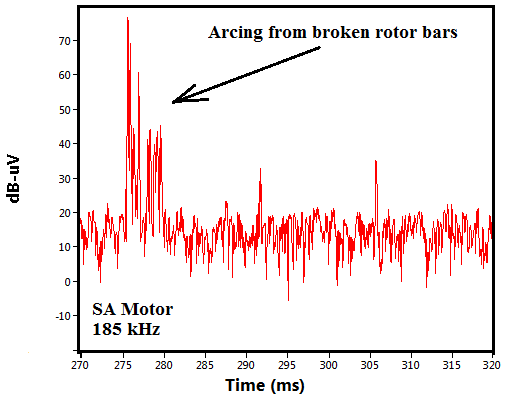

Electro Magnetic Interference (EMI) is produced by electrical and mechanical defects in motors. The precise measurement of EMI will provide a condition assessment for a motor and associated power system. Data is collected during a normal operation with a split core radio frequency transformer (RFCT) paced around the motor power conduit. Data collection is completely passive, no signal is injected into the system. The motor below had recently returned from a shop where broken rotor bars were repaired. Induction motor rotors will frequently develop broken rotor bars.

This EMI Signature indicates broken rotor bars.

An arcing pattern matches the rotor slip speed.

The repairs to the induction motor rotor were not successful all new bars were needed.

Advantages of EMI Testing motors include:

- Test is made with the motor under operating conditions

- Problems are identified early so timely corrective measures can be taken

- The motor, power cables and breaker are evaluated during the test

- Repairs can be verified