EMI Diagnostics: Hydro Electric Generators

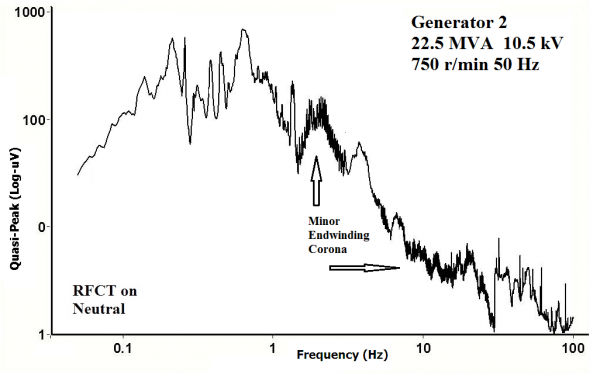

Electro Magnetic Interference (EMI) is produced by electrical and mechanical defects in Hydro Electric Generator systems. The precise measurement of EMI will provide a condition assessment for the entire system, generator, exciter, bus and breaker. Data is collected during normal operation with a split core radio frequency transformer (RFCT) placed around the stator neutral conduit. No permanently installed coupler is necessary to collect EMI data. Data collection by a skilled test engineer requires around one hour. In the example below the OEM recommendation was to replace the stator winding after 25 years of service. No off line tests had indicated there was deterioration. An EMI test was performed followed the next day with a visual inspection. Only minor corona burns were found by the EMI Diagnostic and the inspection. Minor maintenance was needed not stator winding replacement. Millions of dollars were saved. A follow up EMI test confirmed the maintenance was successful.

The curve produced is an EMI Signature.

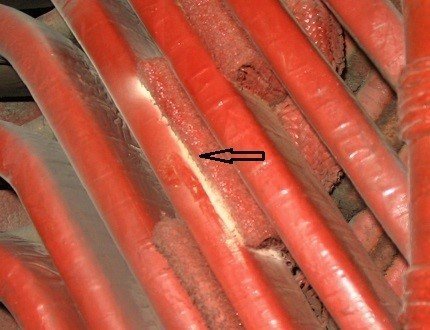

An inspection located minor deterioration.

The EMI patterns seen were identified as minor corona by a test engineer and a location was determined. This pointed to the stator endwindings where deterioration was expected and found. Stator repairs were simple and effective. Advantages of using the EMI Test on Hydro Electric generators are:

- Test is made while the unit is in service

- Problems are identified early so maintenance can be scheduled

- The generator, exciter, voltage regulator, power cables and breaker are evaluated

- Risk of system failures are reduced