Achieving High Quality Remote Transformer Manufacturing Inspections

Connecting Expertise, Innovation and Technology Everywhere

Quality assurance for large power transformer design and manufacturing is critical to ensuring the reliable delivery of energy. Due to travel restrictions driven by COVID-19, most previously planned in-person inspections have transitioned to remote inspections using office-based technologies such as Microsoft Teams™, Zoom or Cisco WebEx®. While these tools work well for everyday business meetings, their capabilities fall short when used for remote inspections.

While some manufacturers are providing reasonable remote factory acceptance test witness surveillance capabilities, manufacturing inspections such as core and coil inspections, pre-vapor phase inspections, pre-tanking inspections and generally any inspection activities which take place off the factory test floor have been greatly impacted. Customer representatives and third-party experts require detailed visibility to collaborate, ask questions and make sure risk areas are addressed.

Inspections are most effective when teams use a remote expert communication platform with the following capabilities:

- High resolution image capture that provides the resolution, focus and stabilization of the camera, not just screenshots of the live-stream feed.

- Successful bandwidth management in challenging environments.

- Collaboration tools for gathering information and, when necessary, troubleshooting.

- Support for multiple participants (10 or more) in a conference.

- Ability to assign user-defined roles to each participant.

Doble investigated more than 20 different remote expert platforms to find one that met all of these necessary requirements.

New from Doble: Remote Expert Inspection Platform

Doble’s new remote expert inspection platform is a secure, web-based, industrial grade solution that, when coupled with Doble’s transformer consulting experts, dramatically improves how manufacturing inspections are performed remotely. We implemented this new platform to:

- Maintain confidence through an independent inspection process.

Doble expert design engineers follow our structured, process-driven methodology to ensure a productive technical inspection. - Provide seamless stakeholder group communication.

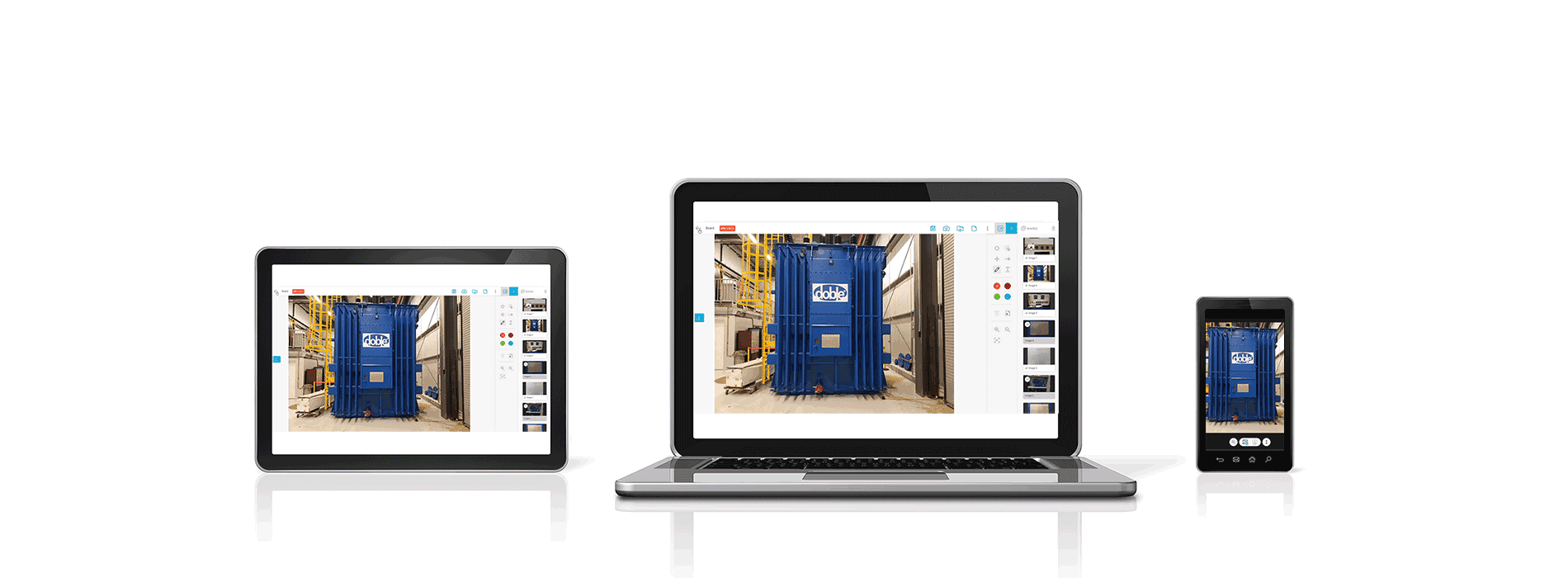

The platform supports multiple participants from the customer, manufacturer and Doble experts and provides high quality video features, even in low bandwidth environments. - Ensure participants can easily log on to the platform.

Participants connect through a web browser on a laptop or any mobile device. No software download is required. - Operate on any device.

The key to successful remote inspections is in the communication software, not in the camera or hardware. Doble’s platform leverages readily available Android™ or IOS® smartphones or tablets and if needed can include leading smart glass wearables technology.

A Quick Application Look: Remote Inspections in Practice

Our remote expert inspection platform provides Doble experts with the ability to conduct many activities from afar, including core and coil inspections. They can easily capture high-quality images of the core during the stacking process, enhancing the live-video inspection for thorough assessment of the various gaps at the core joints or core step blocking, insulating components, duct material and core clamp insulation. Evaluation of each coil assembly would follow to inspect minor insulation, identify misplaced key spacers or other insulating components and inspect crossovers and transpositions.

During pre-vapor phase and pre-tanking inspections, a Doble expert can examine the entire core and coil assembly, cleats and leads structure and cable routings to make sure there is no damaged insulation or clearance issues. Then the team can check the bolted and brazed connections for quality assurance and witness the transformer placement into the tank with the proper clearances and engagement. The superior imaging and collaboration tools provided by our platform ensure remote inspections provide the information necessary to assess whether a transformer is manufactured properly.

Remote Inspections Beyond the Pandemic

While there is no substitute for in-person inspections, remote inspections can be effective with a structured methodology, the proper communication platform and the right experience. Doble believes that once pandemic-related travel restrictions ease, remote inspection will likely remain a part of the customer’s manufacturing processes whether for improved scheduling flexibility or cost reduction. In the future, customers may send a transformer expert on-site, but may also utilize Doble’s remote expert inspection platform to allow for additional inspections or additional customer personnel such as project managers, plant managers or subject matter experts to participate.

Doble’s transformer consulting team is ready to help power and utility companies maintain control and confidence throughout the entire manufacturing quality assurance process.

For more information on Doble’s transformer consulting services and the remote expert inspection platform, please contact your Doble representative.

ADDITIONAL INFORMATION: